The HYUNDAI WIA L230LMS CNC Lathe Turning Center

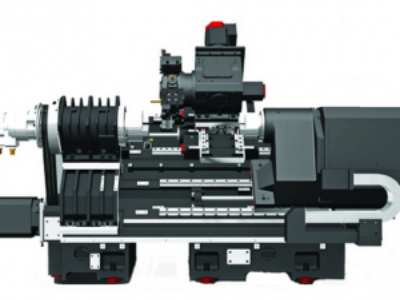

The HYUNDAI WIA L230LMS CNC Lathe Turning Center is a state-of-the-art multi-function machine tool designed to handle complex turning operations with the highest levels of accuracy, speed, and reliability. Manufactured by HYUNDAI WIA

The HYUNDAI WIA L230LMS CNC Lathe Turning Center is a state-of-the-art multi-function machine tool designed to handle complex turning operations with the highest levels of accuracy, speed, and reliability. Manufactured by HYUNDAI WIA, a world leader in precision engineering, the L230LMS combines the power of dual spindles, advanced control systems, and compact design efficiency to deliver outstanding performance for modern production facilities.

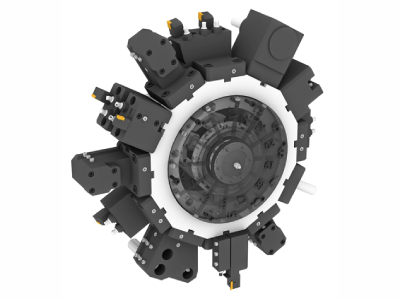

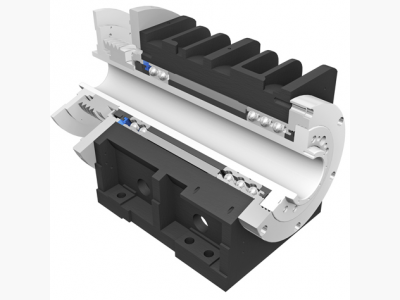

Built with a main spindle and sub-spindle configuration, this turning center enables complete machining of parts in a single setup — minimizing downtime and ensuring dimensional accuracy. The main chuck diameter of 8 inches and sub-spindle chuck of 6 inches (169 mm) allow for a wide range of part sizes, while the bar capacity of 65 mm supports continuous, automated production with bar feeders.

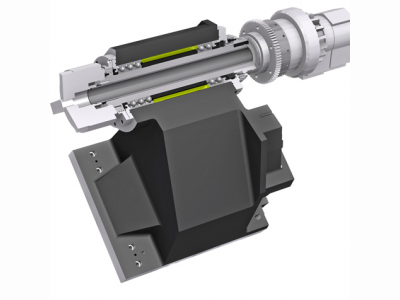

The spindle motor delivers up to 20 HP (15 kW) of power with a maximum speed of 4,000 RPM, ensuring excellent cutting torque for materials like steel, aluminum, and high-strength alloys. The sub-spindle, rated at 7.3 HP (5.5 kW) with speeds up to 5,000 RPM, provides efficient part transfer and secondary operations such as back-side machining.

Precision linear guideways on the X, Y, Z, and ZB axes offer rapid traverse speeds of up to 1,417 IPM (36 m/min), ensuring shorter cycle times and high productivity. The machine’s rigid cast-iron bed construction minimizes vibration, ensuring stable and precise machining even under heavy loads.

Engineered for versatility, the L230LMS is ideal for industries demanding precision and productivity, such as automotive, aerospace, oil & gas, and mechanical engineering. With its advanced CNC control, compact footprint, and multi-tasking capabilities, this machine is a powerful asset for any precision manufacturing setup.

Key Features

-

High-performance dual-spindle CNC turning center

-

Capable of main and sub-spindle operations for complete machining in one setup

-

Main chuck: 8 in / Sub-chuck: 6 in (169 mm)

-

Bar capacity: 2.56 in (65 mm) for automated production

-

High spindle power: 20 HP (15 kW) and 4,000 RPM max speed

-

Sub-spindle power: 7.3 HP (5.5 kW) and 5,000 RPM max speed

-

Rapid traverse speeds: up to 36 m/min on major axes

-

Heavy-duty bed structure for vibration-free precision machining

-

Compatible with Fanuc or Siemens CNC systems

-

Perfect for complex multi-axis turning and mass production applications

Product Details

| Specification | Details |

|---|---|

| Swing Over Bed | 21.65 in (550 mm) |

| Maximum Turning Length | 20.51 in (521 mm) |

| Chuck – Main Spindle | 8 in |

| Chuck – Sub-Spindle | 6 in (169 mm) |

| Bar Capacity | 2.56 in (65 mm) |

| X-Axis Travel | 8.66 in (220 mm) |

| Y-Axis Travel | – |

| Z-Axis Travel | 22.05 in (560 mm) |

| ZB-Axis Travel | 23.23 in (590 mm) |

| X – Rapid Traverse | 1,417 IPM (36 m/min) |

| Y – Rapid Traverse | – |

| Z – Rapid Traverse | 1,417 IPM (36 m/min) |

| ZB – Rapid Traverse | 1,181 IPM (30 m/min) |

| Spindle Power | 20 / 14.7 HP (15 / 11 kW) |

| Maximum Spindle Speed | 4,000 RPM |

| Sub-Spindle Power | 7.3 / 4.9 HP (5.5 / 3.7 kW) |

| Maximum Sub-Spindle Speed | 5,000 RPM |