CK-6130 Flat Bed CNC Lathe Machine

The CK-6130 Flat Bed CNC Lathe Machine is a precision-engineered, high-efficiency turning solution designed for small to medium-sized workpieces. Built for accuracy, stability, and ease of use, this lathe combines advanced CNC technology with a compact, durable flat-bed structure

The CK-6130 Flat Bed CNC Lathe Machine is a precision-engineered, high-efficiency turning solution designed for small to medium-sized workpieces. Built for accuracy, stability, and ease of use, this lathe combines advanced CNC technology with a compact, durable flat-bed structure—making it ideal for workshops, tool rooms, and light industrial applications.

Featuring a maximum rotary diameter of 300 mm and a maximum workpiece length of 350 mm, the CK-6130 provides ample machining capacity for precision parts and components. The spindle speed range of 300–3000 RPM (AC) and 3.0 kW AC main motor deliver the power and versatility required for a wide range of materials, including steel, aluminum, and cast iron.

Its high-precision guideways (260 mm width) ensure smooth and stable movement during operation, minimizing vibration and enhancing cutting accuracy. The machine’s Z-axis travel of 400 mm and X-axis travel of 200 mm provide excellent flexibility for detailed turning operations, while servo-driven motors ensure responsive motion control and consistent performance.

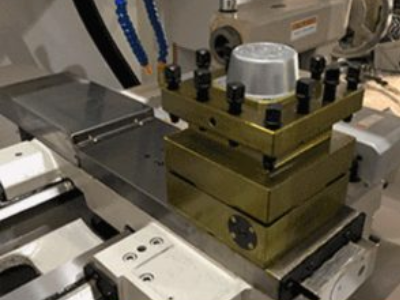

The CK-6130 is equipped with a 4-position automatic carriage and supports an optional tool rack, allowing fast tool changes and efficient multi-operation machining. With a tool size capacity of 20×20 mm and a quick tool change time of 1.7 seconds, it offers both speed and productivity.

For enhanced operational reliability, the tailstock includes a Φ50 mm sleeve with an MT4 taper, ensuring stable support for long workpieces. Its compact size (1630×935×1410 mm) and manageable weight (~1200 kg) make it suitable for both small-scale and educational CNC training environments, as well as industrial part production.

Key Features

-

Compact flat-bed CNC lathe for precision machining

-

Max rotary diameter: 300 mm

-

Max workpiece length: 350 mm

-

Spindle speed range: 300–3000 RPM (AC drive)

-

Main motor power: 3.0 kW AC

-

Servo-controlled X/Z-axis drive for precision movement

-

Repeat positioning accuracy: X – 0.008 mm / Z – 0.001 mm (ISO)

-

4-position automatic tool carriage (standard)

-

Optional tool rack for enhanced versatility

-

Tailstock sleeve: Φ50 mm / MT4 taper for stability

-

Compact footprint and energy-efficient design

-

Suitable for educational, prototyping, and light production applications

Product Details

| Items | Unit | CK6130 |

|---|---|---|

| Max Rotary Diameter on Bed | mm | 300 |

| Max Stroke on Swing | mm | 150 |

| Max Length for Workpiece | mm | 350 |

| Width of Guide Rail | mm | 260 |

| Spindle Speed | (r/min) | 300–3000 AC |

| Spindle Taper | mm | Φ48 |

| Main Motor Power | kW | 3.0 kW AC |

| Z Travel | mm | 400 |

| X Travel | mm | 200 |

| Driving Motor Torque (X/Z) | n·m | Servo 4 / 6 |

| Repeat Position Precision (X/Z) | (ISO) | 0.008 / 0.001 |

| 4 Work Position Carriage | – | Standard |

| Tool Rack | – | Optional |

| Tool Size | mm | 20 × 20 |

| Tool Change Time | s | 1.7 |

| Tailstock Sleeve Travel | mm | 100 |

| Tailstock Sleeve Diameter / Taper | – | Φ50 / MT4 |

| Outer Size (L×W×H) | mm | 1630 × 935 × 1410 |

| Total Weight | kg | 1200 (approx.) |