The HYUNDAI WIA E160A CNC Lathe Turning Center

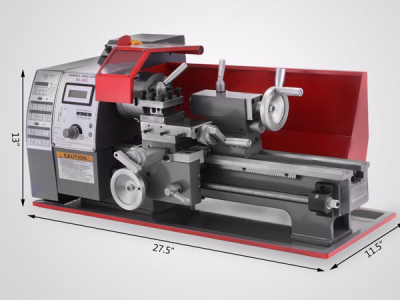

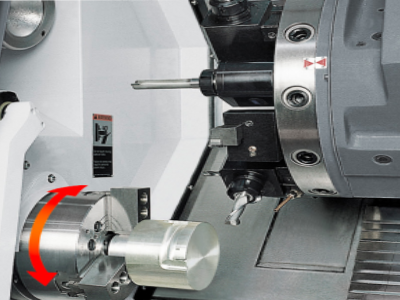

The HYUNDAI WIA E160A CNC Lathe Turning Center is a world-class precision machine tool engineered for high-efficiency metal cutting and superior machining accuracy. Designed and manufactured by HYUNDAI WIA, a global leader in advanced machine tools, the E160A combines robust construction, cutting-edge technology, and intelligent control systems to deliver exceptional performance in any production environment.

The HYUNDAI WIA E160A CNC Lathe Turning Center is a world-class precision machine tool engineered for high-efficiency metal cutting and superior machining accuracy. Designed and manufactured by HYUNDAI WIA, a global leader in advanced machine tools, the E160A combines robust construction, cutting-edge technology, and intelligent control systems to deliver exceptional performance in any production environment.

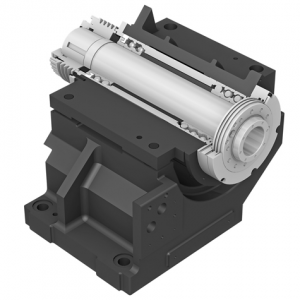

This CNC turning center is ideal for both mass production and custom precision machining. It is equipped with a powerful 22.0 / 18.5 kW spindle motor capable of reaching speeds up to 3,600 RPM, ensuring smooth and precise operation even when working with tough materials like stainless steel, alloy steel, or titanium.

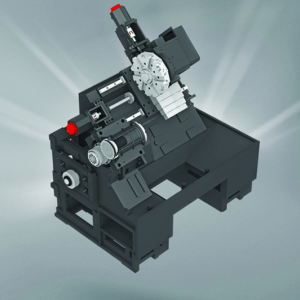

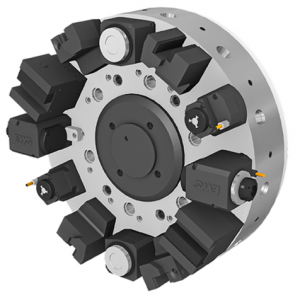

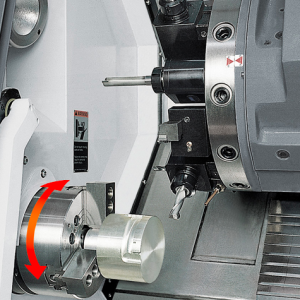

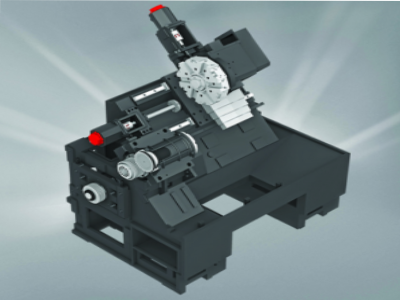

With a swing over bed of 750 mm and a maximum turning length of 720 mm, the E160A accommodates medium to large-sized components. Its A2-8 spindle nose ensures firm clamping stability and enhanced accuracy during high-speed operations. The 12-station turret provides rapid tool changes, allowing multi-step machining processes to be completed efficiently without manual intervention.

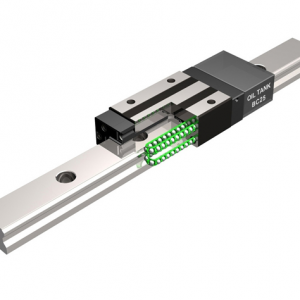

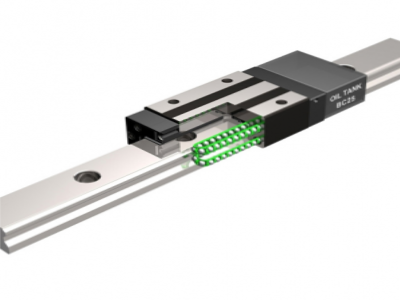

The E160A’s box guideway construction and rigid bed design minimize vibration, enhance tool life, and maintain consistent dimensional precision. Combined with advanced CNC controls (Fanuc or Siemens depending on configuration), it offers operators precise control, fast setup, and smooth automation integration.

Built for reliability and longevity, the HYUNDAI WIA E160A CNC Lathe Turning Center is a trusted solution for industries such as automotive, aerospace, defense, oil & gas, and general manufacturing — where accuracy, speed, and dependability are essential.

Key Features

-

High-speed CNC Lathe Turning Center designed for precision machining

-

Powerful spindle motor (22.0 / 18.5 kW) for demanding cutting tasks

-

Maximum spindle speed: 3,600 RPM for superior surface finish

-

Generous work area: 750 mm swing over bed and 720 mm turning length

-

12-tool turret for multi-operation machining efficiency

-

Rapid traverse rates: 20 m/min (X-axis) and 24 m/min (Y-axis)

-

Heavy-duty cast iron bed for vibration-free performance

-

A2-8 spindle nose for excellent chuck stability

-

Compatible with Fanuc / Siemens CNC control systems

-

Ideal for precision parts, shafts, and mass-production components

Product Details

| Specification | Details |

|---|---|

| Standard Chuck Diameter | 254 mm |

| Swing Over Bed | 750 mm |

| Swing Over Carriage / Cross Slide | 480 mm |

| Max. Turning Diameter | 500 mm |

| Max. Turning Length | 720 mm |

| Spindle Nose | A2-8 |

| Spindle Speeds | 3,600 RPM |

| Spindle Bore / Bar Capacity | 90 / 76 mm |

| Spindle Power | 22.0 / 18.5 kW |

| Rapid Traverse Rates – X / Y | 20 / 24 m/min |

| Number of Turret Stations | 12 |